Evans by Shay Murtagh, in collaboration with EOC Engineers and other partners, proudly contributed to the White Eagle Lodge project, a remarkable architectural feat that blends spiritual significance with cutting-edge design and engineering.

Project Overview

The White Eagle Lodge in Hampshire, designed by James Gorst Architects and engineered by Eckersley O’Callaghan (EOC), is part of a larger complex intended as a spiritual centre for the White Eagle Lodge community. The project replaces an older temple with a new structure, combining resilient, long-lasting materials.

Design and Construction Challenges

The temple's design is based on sacred geometries and harmonious mathematical ratios. A significant feature is the 12m-diameter circular roof, focusing on a central altar aligned with the original building's lay lines. The roof is topped with a glass and timber lantern, designed by EOC, featuring larch glued and laminated timber frames converging at an oculus above the altar.

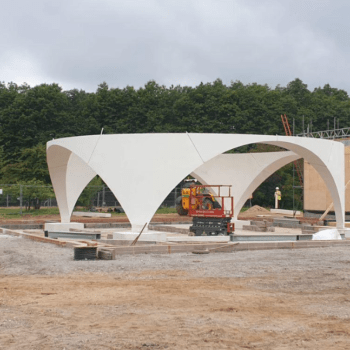

Pendentive Formations

The temple's unique pendentive formations, with arched openings to the cardinal points, presented a significant engineering challenge. These formations carry horizontal thrust and gravity loads into four pad foundations. The subfloor employs a low-energy labyrinth for cooling, drawing fresh air from beneath the suspended concrete floor.

Precast Concrete Solution

Initially conceived as a natural load-bearing stone structure, the temple was eventually constructed using precast concrete for cost-effectiveness and reduced design and execution risks. The cast stone cylinder is divided into four quadrants, each consisting of three structurally visible pieces. The detailing of shadow gaps and construction tolerances was crucial, given the close scrutiny by building users.

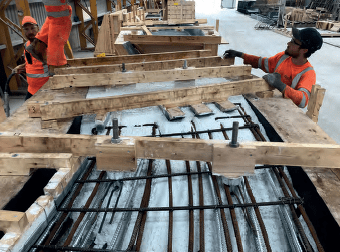

Manufacturing and Installation

Evans by Shay Murtagh played a pivotal role in manufacturing the individual component parts at its Derbyshire factory. The structural carcass and ribs were assembled, and the mould shutter faces formed around the ribs in layers to create curved faces. The concrete mix design, provided in-house, was a light-coloured Italian Dolomite coarse and fine aggregate incorporating Portland cement and some GGBS replacement. The finished concrete faces were acid-etched for a softened natural effect.

Reinforcement and Environmental Considerations

A reduced reinforcing bar spacing minimised surface cracking, and relatively small 12mm-diameter bars were used to limit the carbon footprint. The embodied carbon score of the structure was 265kg embodied CO2/m2, which is low for a single-storey building.

On-Site Assembly

The on-site assembly was carefully orchestrated, with the units brought together and locked into alignment. The weight and scale of the units necessitated their early installation during the construction program.

The White Eagle Lodge project is a fine testament to the coordination and communication across the design and site delivery teams. It stands as an elegant production, showcasing Evans by Shay Murtagh's commitment to innovative design and precision in architectural precast concrete.